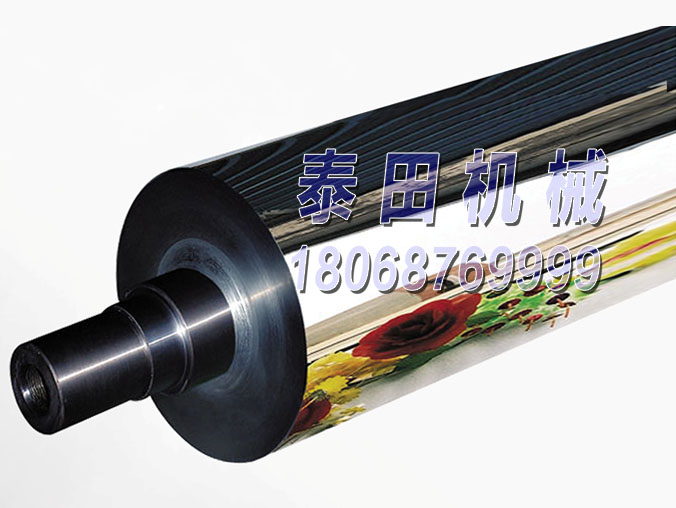

Introduction of mirror roller

1. Introducing the original polishing and polishing facilities in the United States, the highest finish can reach Ra0.01 (finish level 14), is the highest level of mirror roller processing equipment in China.

2. The mirror surface can be machined on the surface of various materials to ensure the flatness, balance, non-circularity and coaxiality of the roller surface to meet the requirements.

3. Suitable for PP, PT, PE, ABS, PVC and other plastics calendering, matting treatment, leather ironing calendering, textile fabric ironing, paper calendering, matting treatment.

4. The material is made of 45# seamless steel tube or alloy steel, which is made by heat treatment and mechanical processing. The temperature difference between cooling and heating is not greater than 1 0.01mm, the thermal deformation is less than or equal to 0. Straightness < 0.005mm, beating < 0.005mm, coaxiality < 0.005mm, surface hardness HRC55-58, hardness HRC62 after chrome plating and polishing, thermal deformation is not more than 0.01mm.

Two, custom instructions

Please provide the size (diameter, length) of custom rollers and other special requirements, and fax the design drawings to our company. If you do not have design drawings, please contact us, the engineer will provide you with professional solutions.